Aluminum Casting Alloys Chart . Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. Data for several selected aluminum alloys are compiled in this appendix. Wrought compositions and cast compositions. The materials table given below displays the mechanical properties of some common aluminum casting alloys. Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. It is convenient to divide aluminum alloys into two major categories: The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). A further differentiation for each. Chapter 1 aluminum casting applications 1. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight.

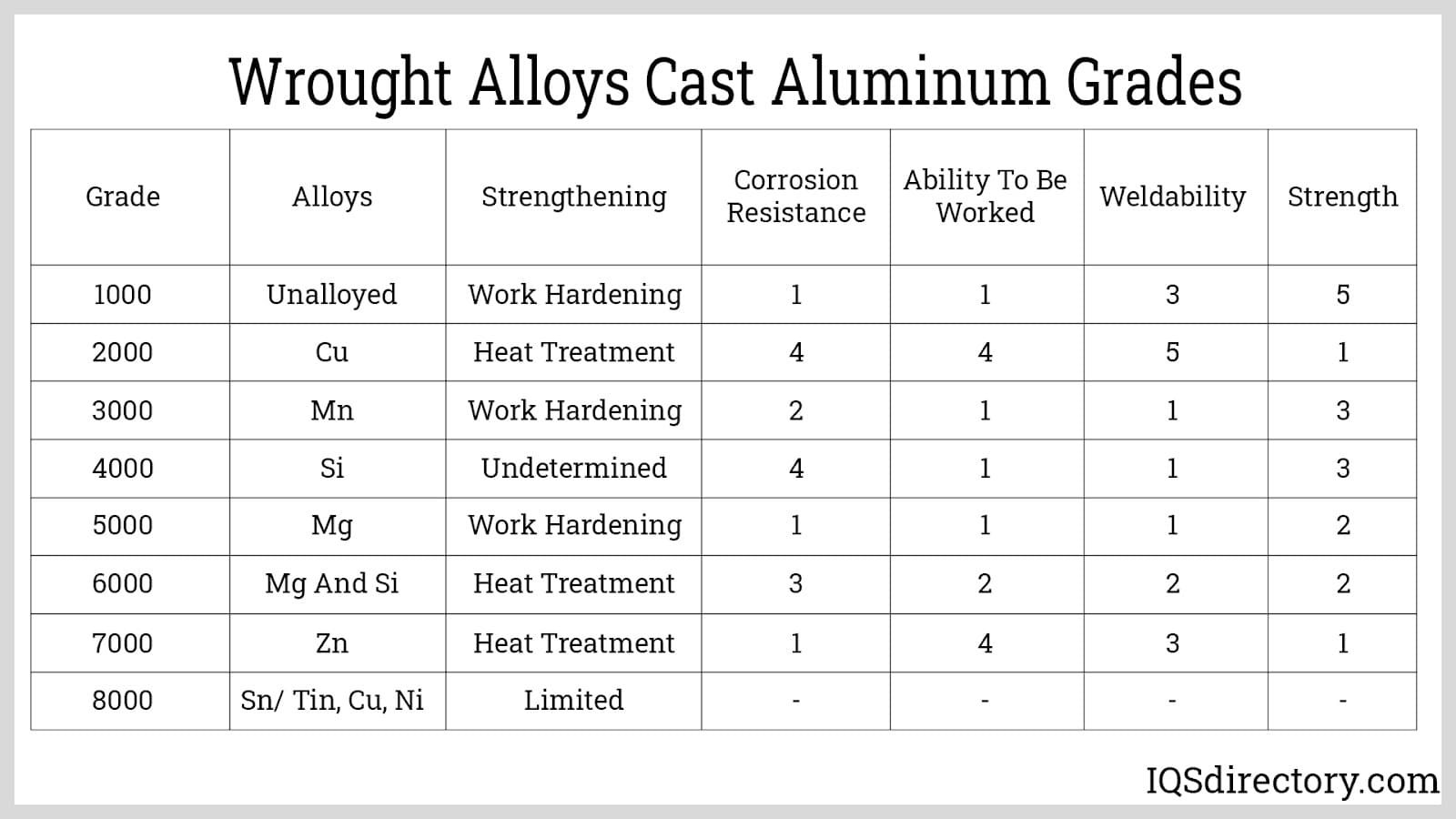

from www.iqsdirectory.com

Chapter 1 aluminum casting applications 1. A further differentiation for each. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). Data for several selected aluminum alloys are compiled in this appendix. Wrought compositions and cast compositions. The materials table given below displays the mechanical properties of some common aluminum casting alloys. Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. It is convenient to divide aluminum alloys into two major categories:

Aluminum Casting What Is It? How Is it Made? Advantages

Aluminum Casting Alloys Chart A further differentiation for each. Chapter 1 aluminum casting applications 1. The materials table given below displays the mechanical properties of some common aluminum casting alloys. It is convenient to divide aluminum alloys into two major categories: Wrought compositions and cast compositions. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). A further differentiation for each. Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. Data for several selected aluminum alloys are compiled in this appendix. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight.

From cutstom.com

Aluminum and his alloys Custom Online Laser Cutting Aluminum Casting Alloys Chart Chapter 1 aluminum casting applications 1. Wrought compositions and cast compositions. It is convenient to divide aluminum alloys into two major categories: A further differentiation for each. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). Data for several selected aluminum alloys are compiled in. Aluminum Casting Alloys Chart.

From www.giessereilexikon.com

Aluminum ingot casting alloys Aluminum Casting Alloys Chart It is convenient to divide aluminum alloys into two major categories: Data for several selected aluminum alloys are compiled in this appendix. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc,. Aluminum Casting Alloys Chart.

From mungfali.com

Aluminum Extrusion Alloys Chart Aluminum Casting Alloys Chart It is convenient to divide aluminum alloys into two major categories: A further differentiation for each. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. Data for several selected aluminum alloys are compiled in this appendix. Our global standards chart will help you to compare and contrast the. Aluminum Casting Alloys Chart.

From samuelhudson.z19.web.core.windows.net

Aluminum Casting Alloys Chart Aluminum Casting Alloys Chart A further differentiation for each. It is convenient to divide aluminum alloys into two major categories: Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7%. Aluminum Casting Alloys Chart.

From www.factmr.com

Aluminium Alloys Market Global Forecast & Outlook 2032 Aluminum Casting Alloys Chart A further differentiation for each. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). Wrought compositions and cast compositions. Chapter 1 aluminum casting applications 1. Data for several selected aluminum alloys are compiled in this appendix. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity,. Aluminum Casting Alloys Chart.

From www.metalex.co.uk

Aluminium Alloy Specifications Metalex Aluminum Casting Alloys Chart The materials table given below displays the mechanical properties of some common aluminum casting alloys. Wrought compositions and cast compositions. Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. Chapter 1 aluminum casting applications 1. Aluminum (al) die casting alloys have a speci c gravity of approximately. Aluminum Casting Alloys Chart.

From castaluminumreakuji.blogspot.com

Cast Aluminum Density Of Cast Aluminum Aluminum Casting Alloys Chart Data for several selected aluminum alloys are compiled in this appendix. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. Our global standards chart will help you to compare and contrast. Aluminum Casting Alloys Chart.

From www.lightmetalage.com

AlAlloysTable I Alloy Elements Light Metal Age Magazine Aluminum Casting Alloys Chart Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. The materials table given below displays the mechanical properties of some common aluminum casting alloys. It is convenient to divide aluminum alloys into two major categories: Chapter 1 aluminum casting applications 1. Wrought compositions and cast compositions. A. Aluminum Casting Alloys Chart.

From www.rnbearings.cc

INTERNATIONAL ALUMINUM & ALUMINIUM ALLOY COMPARISON TABLE Technology Aluminum Casting Alloys Chart A further differentiation for each. It is convenient to divide aluminum alloys into two major categories: Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. Data for several selected aluminum alloys are compiled in this appendix. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability. Aluminum Casting Alloys Chart.

From www.iqsdirectory.com

Aluminum Casting What Is It? How Is it Made? Advantages Aluminum Casting Alloys Chart The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. Our global standards chart will help you to compare and contrast the different specifications of. Aluminum Casting Alloys Chart.

From www.scribd.com

Aluminum_Filler_Alloy_Selection_Chart Alcotec.pdf Alloy Welding Aluminum Casting Alloys Chart Chapter 1 aluminum casting applications 1. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357. Aluminum Casting Alloys Chart.

From www.techni-cast.com

Aluminum Bronze Alloys TechniCast Corporation Aluminum Casting Alloys Chart The materials table given below displays the mechanical properties of some common aluminum casting alloys. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively).. Aluminum Casting Alloys Chart.

From docslib.org

Brass and Bronze Standard Casting Alloys Chart of Specifications DocsLib Aluminum Casting Alloys Chart Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. A further differentiation for each. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight. Aluminum Casting Alloys Chart.

From www.researchgate.net

Classification of cast aluminum alloys and wrought aluminum alloys (a Aluminum Casting Alloys Chart The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. Data for several selected aluminum alloys are compiled in this appendix. Aluminum (al) die casting alloys have a speci c gravity of. Aluminum Casting Alloys Chart.

From materialschoollavonne.z21.web.core.windows.net

Aluminum Grades Chart Pdf Aluminum Casting Alloys Chart The most common aluminum alloy for sand casting, gravity casting and low pressure casting is the 356 and 357 (6% and 7% si respectively). Wrought compositions and cast compositions. Data for several selected aluminum alloys are compiled in this appendix. The materials table given below displays the mechanical properties of some common aluminum casting alloys. Aluminum (al) die casting alloys. Aluminum Casting Alloys Chart.

From www.rechargecolorado.org

Aluminum Alloy Properties Chart Best Picture Of Chart Aluminum Casting Alloys Chart Wrought compositions and cast compositions. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. Chapter 1 aluminum casting applications 1. Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. The materials table given below displays. Aluminum Casting Alloys Chart.

From diecastingoem.com

Comparison table of diecast aluminum alloy gradesEU standard EN1706 1998 Aluminum Casting Alloys Chart Data for several selected aluminum alloys are compiled in this appendix. Our global standards chart will help you to compare and contrast the different specifications of aluminium alloys between the uk and other. A further differentiation for each. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. The materials table given below displays the mechanical. Aluminum Casting Alloys Chart.

From www.researchgate.net

CHEMICAL COMPOSITION OF ALUMINIUM ALLOY 6063 Download Table Aluminum Casting Alloys Chart Data for several selected aluminum alloys are compiled in this appendix. Wrought compositions and cast compositions. In handheld devices, aluminum castings provide emi/rfi shielding, rigidity, and durability with minimal weight. Aluminum (al) die casting alloys have a speci c gravity of approximately 2.7 g/cc, placing them among the lightweight structural metals. The most common aluminum alloy for sand casting, gravity. Aluminum Casting Alloys Chart.